Christmas through the Eyes of a Candle

Candle, Candle Burning Bright

The Christmas season in Germany wouldn’t be complete without the warm glow of candles on an Advent wreath. But where does the wax for these candles come from? How long does it take to make a candle? And what is a “master wax chandler”?

Candles actually have an intriguing link to the age of the dinosaurs. Millions of years ago, organic matter accumulated on the ocean floor, developing into so-called putrefactive sludge due to lack of oxygen. In simple terms, through the natural forces of sedimentation, intense pressure and heat, this sludge transformed into crude oil, the raw material from which paraffin wax is extracted today.

Kerosene is a byproduct of the oil industry. | Picture (Detail) © mauritius images / Westend61 / Serjunco

From oil refinery to store shelf: how an Advent wreath candle is made

Paraffin, a byproduct of the oil purification process, once had limited applications but is today the primary material in candle production, says Stefan Thomann from the European Candle Manufacturers Association. Paraffin is used year-round, often blended with plant-based waxes, to make candles. However, as Thomann notes, Christmas is peak season for candles. In Germany, the most popular Christmas candles are Advent wreath candles, candles in glass holders and tealights, commonly sold at discount retailers like Aldi and Lidl. IKEA, however, remains the favourite destination for buying candles.

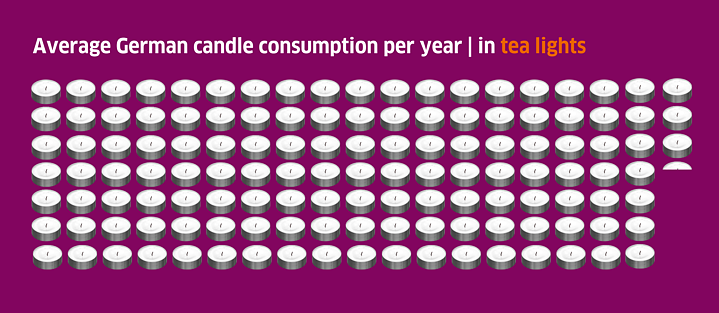

Every year, the average person in Germany buys 1.94 kilograms of candles. This is the equivalent of 129.3 tealights (if each tealight weighs 15 grams). | Graphic © Lena Maurer; Picture (Teelicht) © Francesco Milanese via Canva.com

Candle production – once a guild tradition, now a huge business

Franz Fürst laughs when he hears such figures. As a fifth-generation chandler and Munich’s last “master wax chandler”, he continues the tradition of crafting candles according to an ancient technique. Every hour, his workshop produces a two-centimetre-thick, 220-metre-long strand of candles, resembling a rope coiled around a drum. This wax rope is then cut by hand, dipped in ink and tapered. In a workshop like Fürst’s, a maximum of 1,000 candles are made a day. For him, industrially produced candles and hand-crafted candles are two entirely different products.

It takes time to produce drawn candles. | Picture (Detail) © picture alliance / Peter Kneffel | Peter Kneffel

A craft handed down through generations: Wachszieherei Fürst

Chandler Fürst’s office is located in the south of Munich, in a dark red building in the middle of a residential estate, barely distinguishable from the surrounding houses. Only a golden sign at the entrance, bearing the name “Wachszieherei Fürst”, reveals Franz Fürst’s profession. In his first-floor office, he is busy processing Christmas orders.Founded in 1862, Fürst’s business has seen many changes over the years. In recent times, the company has faced major challenges, including the closure of its store near Munich Cathedral due to unaffordable rent. At one point, Franz Fürst even considered closing the business for good, but his loyal employees convinced him to keep going. Today, he continues to run the business, albeit on a smaller scale.

What you need to know about making candles

Fürst has spent his life accumulating knowledge about candle-making. Even as a child, he played in his family’s workshop. The secret to candle-making lies in the precise composition of the wax, he explains. Fürst’s candles are made from a blend of kerosene, stearin, hard wax, beeswax and a secret ingredient – closely guarded in a leather-bound book. Under no circumstances will he reveal what it is.

Wax chandler Franz Fürst knows all about candles. | Picture (Detail): © privat

Drawn candles create a particularly warm light. | Picture (Detail) © Faiza via Unsplash

What about the environmental impact of candles?

Master chandler Franz Fürst explains that burning a candle in a room is not harmful to humans. However, it is not known how much CO2 the different types of wax emit, says Thomann, representative of the European Candle Manufacturers Association.The environmental impact of candle production depends on the production process, the transportation route and the type of wax used. Palm wax is sometimes linked to deforestation, while paraffin wax is derived from a fossil fuel. Beeswax sourced from local beekeepers may be the most environmentally friendly option, but for the industry it’s not a viable alternative. Beeswax currently accounts for less than 1% of the raw materials used in candle production worldwide. It would have to be sourced on a global scale and the costs would be far too high, says Thomann.

So finding a truly sustainable candle is no easy task, as each type has its advantages and disadvantages. Perhaps we should follow the example of Franz Fürst’s loyal customers: invest in just a few, high-quality candles at Christmas and enjoy their uniquely warm and lasting glow.